Supply Chain & Logistics

Location development

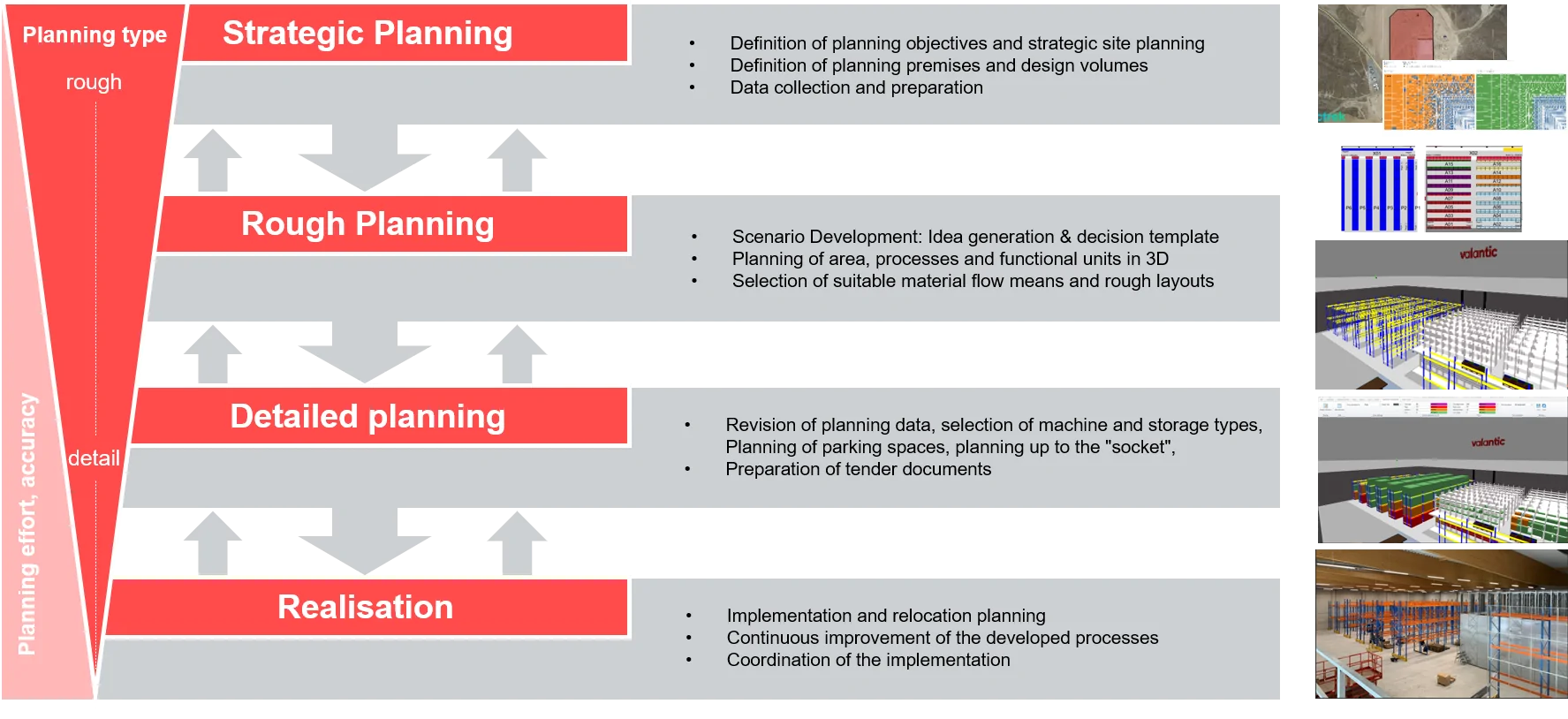

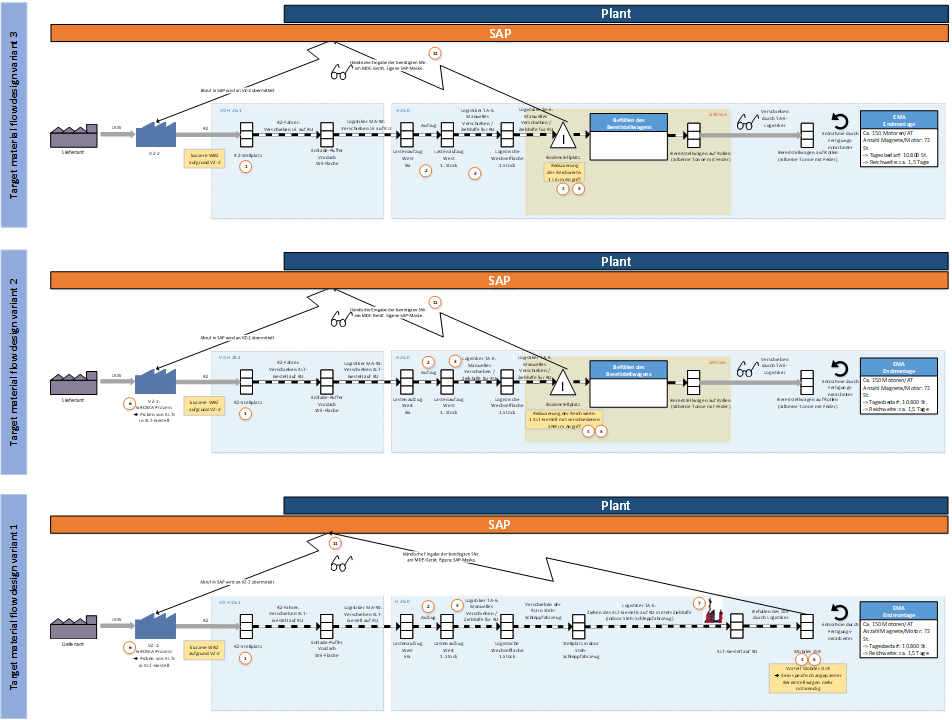

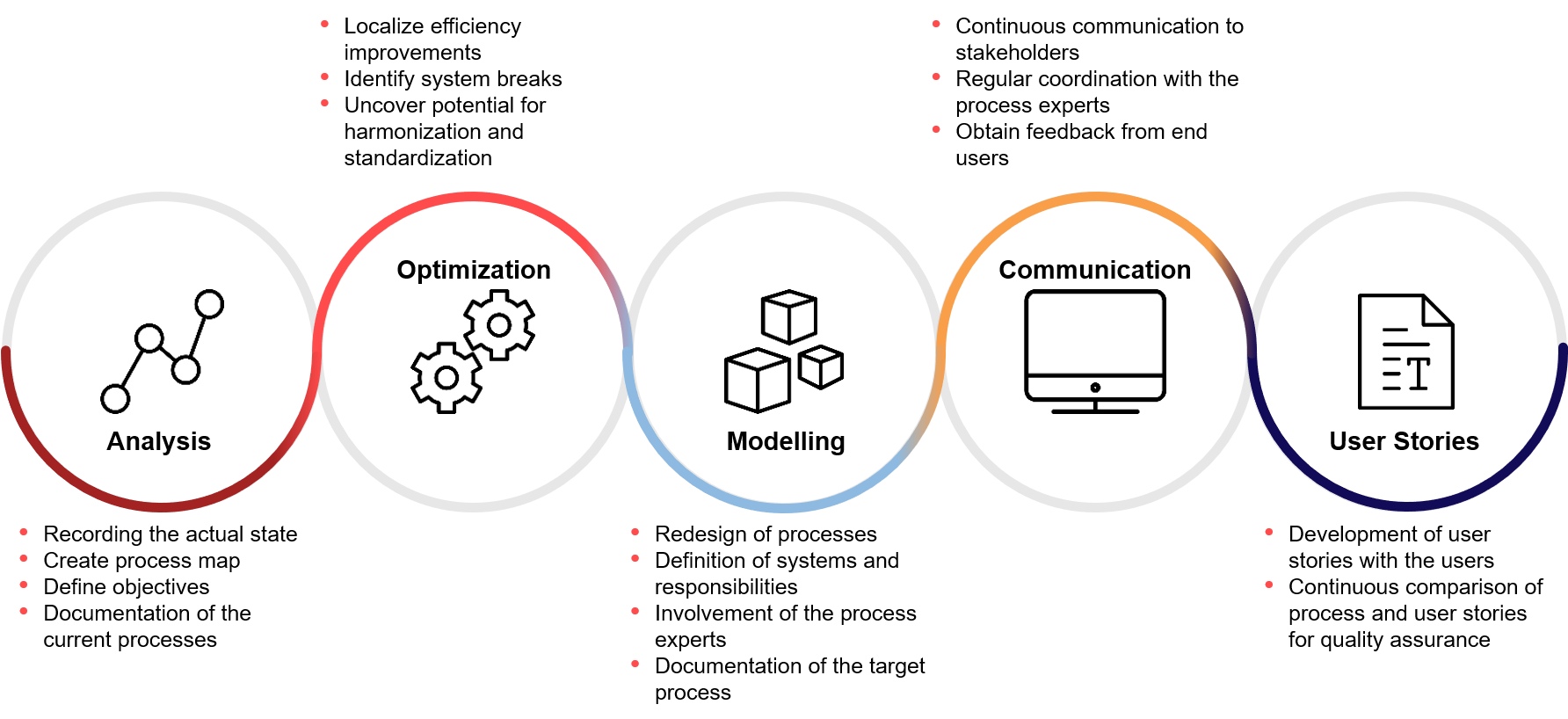

For numerous businesses, their geographical presence and the value generated at that site constitute the heart of their corporate operations. This area presents a multitude of challenges that are critical for the prosperous evolution of the company. The subjects covered include planning the layout of manufacturing facilities and warehouses, designing material flows, and crafting processes. Based on specific needs, additional elements like organized tender management or assistance during the initial operational phase can be pivotal for triumph.