Strategy consulting and digital platforms for Industry 4.0

Smart Industries & Industry 4.0

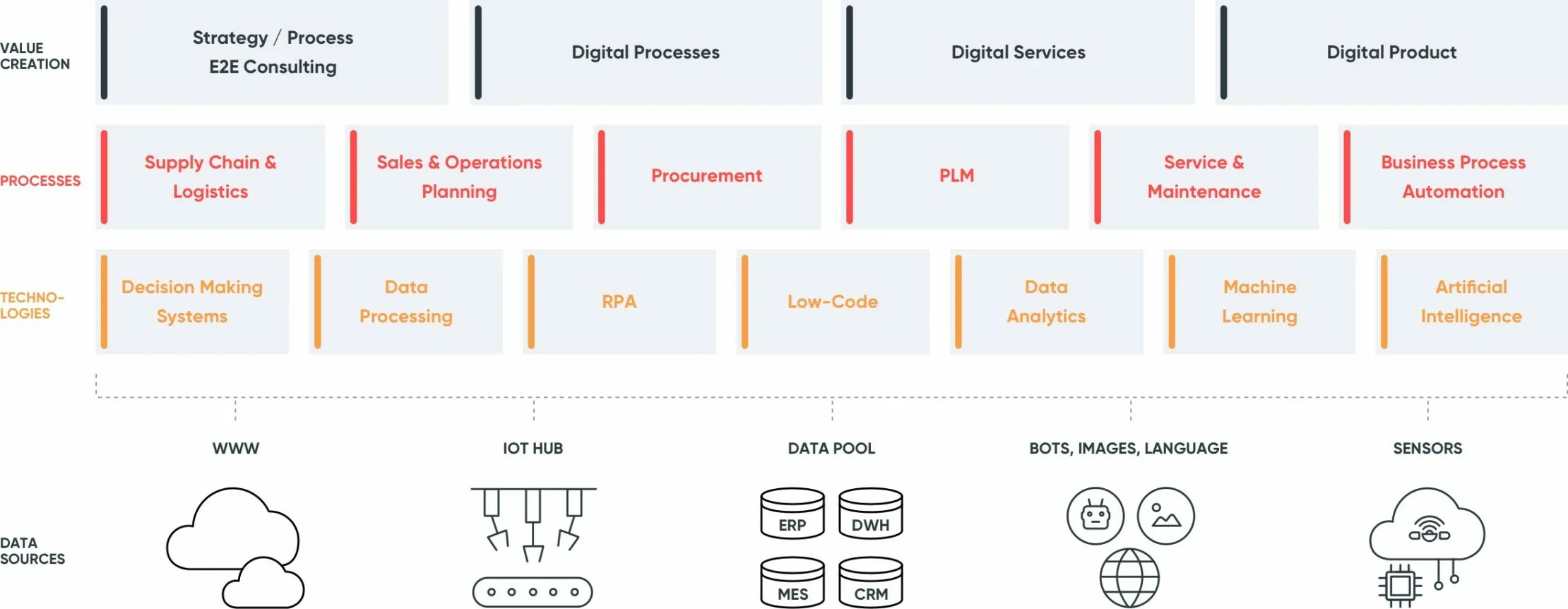

Companies worldwide are in the midst of digitally transforming their production and value chains: Digital processes, digital products and digital services are at the core of corporate transformations, with the aim of digitally transforming the entire value chain end-to-end in the sense of Industry 4.0.

Networked production and logistics chains, as well as machines, systems and sensors intercommunicating via the Internet of Things, significantly optimize the efficiency and quality of all the processes – while simultaneously enabling considerable cost savings and productivity gains, e.g. through reduced throughput times and inventories, and improved maintenance cycles.

Digital 2030: Learn all about digital trends and technologies that will shape your business

Get c-level executives insights from more than 700 decision makers and learn how to harness the power of applied ai. Download our new Trend Study 2030!

valantic creates added value through digital processes, products and services. This is achieved by connecting a wide range of data sources with cutting-edge technologies to create a fully integrated system landscape.

For more than 40 years, valantic has been a trusted partner of its customers for digitally transforming their processes, creating digital services and realizing made-to-measure software solutions – based on our own products, our partners’ products and using bespoke solutions.

Our customers include prominent companies such as Alcon, BBC Cellpack, Continental, Grenzebach, Hohner, KNAPP, Krones, Rosenbauer, SEW EURODRIVE, Seepex, Smiths Detection, Tecan, Vodafone and many more. We cover a wide range of industries – from mechanical and plant engineering, industrial groups and retail, life science and pharmaceuticals to aerospace technology, the automotive industry and the telecommunications industry. We support our customers in digitally transforming their processes, products and services in all areas and making these smarter.

Our services are almost always based on Advanced Cloud Services that let us implement wide-ranging digitization projects in multiple and hybrid cloud environments. As an Advanced Amazon Web Services (AWS) Partner, SAP Cloud Focus Partner and SAP Extended Business Member, Certified Platinum Partner of Camunda and Focus Partner of PTC, our product partnerships provide a state-of-the-art technology platform for our solutions.

The high quality and acceptance of our services are also enhanced by our many association partnerships, including those with the German Broadband Association (BREKO), Bundesvereinigung Logistik (Federal Logistics Association, BVL), House of Energy, Verband Deutscher Maschinen- und Anlagenbau (German Engineering Federation, VDMA), and the Austrian Verein Netzwerk Logistik (Association for Network Logistics, VLN). As consortium leader of the research project “iLaPark – Intelligent Charging and Parking in Parking Garages” funded by the German Federal Ministry for Economic Affairs and Energy (BMWi), we invest in research and development in the field of e-mobility.

Our Smart Industries and Industry 4.0 Services

- 01 What Actually Are Industry 4.0, Smart Industries and IIoT?

- 02 Supply Chain Management & Logistics

- 03 Supply Chain Consulting

- 04 Supply Chain, Performance and Logistics Management

- 05 Sales & Operations Planning (S&OP)

- 06 Procurement Consulting

- 07 Digitization in E-Procurement

- 08 Product Lifecycle Management (PLM)

- 09 Business Process Management (BPM)

- 10 Maintenance & Service Using IIoT Technology

- 11 Device Management Using IoT and Digital Twins

- 12 Advanced Cloud Technologies & Services

- 13 Low-Code

- 14 Carbon Footprint, German Supply Chain Act and Taxonomy

- 15 Our Reference Customers

- 16 Blog News From Smart Industries

- 17 Our Latest Whitepapers

- 18 Our Top Events

- 19 Job Vacancies Relating to Smart Industries

- 20 Contact To Your Industry 4.0 Consultant

What Actually Are Industry 4.0, Smart Industries and IIoT?

Industry 4.0 refers to the fourth industrial revolution, triggered by digitization and the increasing networking of people, machines and products.

Industry 4.0 affects all areas of the economy. The productivity and efficiency of production processes, for instance, can be enhanced with digitization, networking and automation. Production is becoming much more flexible through Smart Industry meaning that, in many areas of manufacturing, automated processes and production can e.g. switch between different operating modes very rapidly. Smart Industry 4.0 solutions conserve resources and optimize goods logistics and supply chains.

Using all the data available makes is possible to provide comprehensive analytics and services, resulting in a more customer-centric economy.

Four central terms are associated with Industry 4.0:

- Internet of Things technology describes the control and networking of digital products and services.

- Industrial Internet of Things extends this concept to industrial plants.

- Cloud Computing enables the flexible and independent use of digital offerings.

- Big Data describes the possibility of using algorithms to extract added value efficiently from the data accumulating in the course of Industry 4.0.

According to the German Federal Ministry of Economics and Climate Protection, the term Smart Industry encompasses the industrial, manufacturing-specific aspects of Industry 4.0, including the areas of Smart Factory and Industrial Internet of Things.

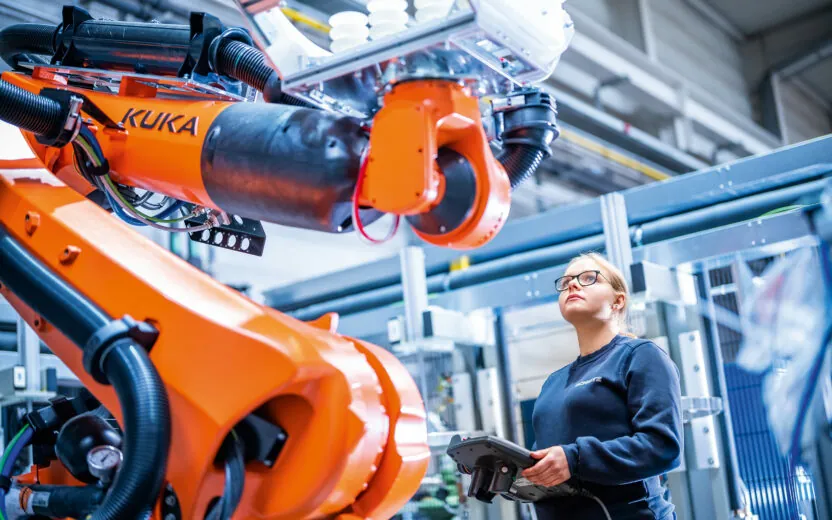

Industry is mutating into a networked, digital and therefore much more productive and efficient smart industry. Smart Industry solutions cover the areas of Smart Factory in conjunction with the Industrial Internet of Things (IIoT). This refers to the digital networking of plants and systems to ensure automated and data-driven production. In doing so, connectivity is realized e.g. through sensors and gateways that bring production and manufacturing facilities online and enable outside control and monitoring.

This automation requires technologies that are compatible, able to intercommunicate and, besides controlling the production facilities, also enable e.g. automatic planning of supply chains and logistics and run over secure networks. In this way, they allow intelligent, all-encompassing manufacturing and movement of goods. Connecting bespoke customer requirements in Industry 4.0 can also add value. Smart industries allow a much more efficient use of resources and sustainable management, while simultaneously increasing the productivity and speed of plant and machinery.

The Internet of Things (IoT) is a collective term for technologies that enable physical and virtual objects to be networked with each other and made to work together through informational and communication technologies.

Unlike the Internet of Things (IoT), the Industrial Internet of Things (IIoT) does not focus on the consumer sector, i.e. the end user. Rather, the IIoT is about the connectivity of devices and production equipment in industry.

Our Competences & Services

Industry 4.0 at its best!

Our 400-plus Smart Industries experts are proven specialists when it comes to the core topics of Industry 4.0 and the Industrial Internet of Things (IIoT): from digitization in E-Procurement and Performance Management to Logistics Management and Sales & Operations Planning (S&OP) to Product Lifecycle Management (PLM) and Business Process Management (BPM). We also help our customers implement their sustainability strategies, such as reducing their carbon footprint.

Supply Chain Management & Logistics

Digitization of the Supply Chain

valantic is the proven partner for helping companies digitally transform their business processes end-to-end, optimize their value chains and enhance their logistics performance.

From integrated process and IT consulting to implementing the IT systems, we accompany our customers in the areas of Supply Chain Management (SCM) and Production, Logistics, Supplier and Performance Management.

Supply Chain Consulting

Dynamic shifts in the economy, trade, and the environment are posing significant challenges for companies striving to remain competitive. HÖVELER HOLZMANN offers expert guidance on how to devise a farsighted strategy for managing all of your processes and develop a state-of-the-art, digitally optimized supply chain. Our consultancy helps companies to benefit from efficiency improvements within the supply chain, allowing them to cut costs and optimize their working capital.

We initially conduct a comprehensive assessment to identify the present state of your supply chain. Following the assessment, we formulate detailed, customized measures to enhance individual planning tasks to ensure the seamless operation of all your value-chain processes. Whether this involves sales planning, inventory and production planning, material requirements planning, or logistics, we meticulously examine every level of supply chain management.

Supply Chain, Performance and Logistics Management:

Shaping the Logistics of Tomorrow

Technological innovations create new opportunities when designing logistics processes and their structures, resulting in faster and more flexible customer service. Choosing the right software and hardware technology and tailoring the process design accordingly are emerging as a central success factor in logistics which must be designed to fully exploit innovative potential is tomorrow’s world. Using modern-day management and logistics methodologies and technologies, valantic helps companies set up robust logistics structures and high-performance supply chains, optimize their digital processes and eliminate existing digitization gaps. Click the link for more information on logistics planning and logistics services.

The complexities of global supply chains and the associated cost pressures pose risks for the supply of materials. Intransparency and vulnerable processes are just two of the main causes of unstable supply chains. In such cases, immediate action is needed to safeguard supply performance, maintain customer satisfaction levels, and minimize follow-up costs.

Sales & Operations Planning

S&OP in the Age of Digital Transformation

In times of increasingly volatile markets, tougher competition and automated production processes, industrial companies face the challenge of managing their S&OP processes transparently across projects and departments. Only in this way will they be able to react quickly and flexibly to changes and hold their own against the competition.

A real-time capable software suite operated on the basis of an on-premises, managed or cloud model (depending on customer requirements) lets planning managers coordinate sales plans, production capacities and raw materials across all planning horizons with great efficiency. From accurate sales plan forecasts to detailed production planning and real-time availability checks, a high-quality planning tool integrates all planning levels and renders changes transparent for all stakeholders in real time.

As experts in the field of Sales & Operations Planning (S&OP), we work closely with various technology vendors. In doing so, valantic’s decision on the technologies to be used is always synchronized precisely with the customer’s unique situation. Examples of these technologies include:

Procurement Consulting

The goal of procurement optimization is to improve the competitiveness of your company. Relying solely on cost optimization no longer suffices for achieving this objective.

Consequently, we help our customers to systematically identify and pragmatically reduce their input prices. This also entails the sustainable transformation of the purchasing organization with a view to digitalized high-performance processes and optimal purchasing structures and strategies. Rounding out our portfolio, we offer procurement-staff training in the form of coaching on the latest purchasing tools and methods.

Discover HÖVELER HOLZMANN’s Procurement Consulting & Optimization portfolio

Digitization in E-Procurement

Effective Management of Cross-Supplier Procurement Processes

E-procurement solutions expedite the entire procurement, supplier management and payment process, resulting in significant reductions in costs and lead times. The source-to-pay and purchase-to-pay processes are optimized and supplier relationships are improved through Supplier Management.

Our valantic experts provide all the essential services – from process consulting to implementation – needed to digitally transform our customers’ procurement processes and automate the entire source-to-pay process across all subsidiaries.

When implementing our customer projects, valantic works with various technology partners and technologies, including

- spend management company ivalua and

- the SAP Ariba e-procurement solution.

Product Lifecycle Management (PLM)

Product Lifecycle Management (PLM) integrates all data, processes, business systems and employees in a product or service lifecycle. PLM from valantic generates many unbeatable benefits:

- Shortened time-to-market through automated data exchange along the supply chain

- Efficient information management in the extended enterprise, from the initial product idea to recycling

- Enhanced process dependability through maturity-driven workflow management

- Quality standards and compliance with norms and standards, enforced cost-effectively through automation

- Shorter process throughput times through best practices and the automation of routine activities

- Targeted identification of weak points, controlled readjustment, shortened time-to-manufacturing

valantic offers the following services for this:

- Assistance in choosing a suitable PLM system

- Technical and programmatic help, from planning to operating an integrated PLM solution

- Modernization of PLM-related processes and systems

Product Lifecycle Management (PLM) with valantic

PLM eliminates inefficiencies, bottlenecks and wasted time, and brings order to chaos.

Process Digitization Using Business Process Management (BPM)

Competition, shrinking margins and, not least, staff shortages are forcing companies to optimize their business processes. Decisive success factors here are efficiency, quality and transparency, and the systematic digitization of processes can make an important contribution. This does not just mean describing the processes in documents, however, but also using applications to help control them and, wherever possible, using data as the basis for process-internal decisions.

Process digitization starts with analyzing and designing the processes – ideally based on a standard such as BPMN (Business Process Modeling and Notation), a defined language for describing business processes. Decision points in processes are described in DMN (Decision Modeling and Notation) and anchored in the process in the form of business rules and decision tables. Rules that change can then be easily adapted and applied under the new conditions.

Automation takes the form of implemented software based on a BPM engine such as Camunda BPM. Solutions such as Camunda form the integration platform for interconnecting all systems involved in the process and provide process monitoring, optimization analysis and process management features. This is needed, as well, since thousands of processes may be running continuously every day.

Process automation – The core of any digitalization strategy

Efficient process automation is one of the greatest challenges for companies today. At the same time it also offers enormous potential for staying on the growth track and reaping the…

Maintenance & Service Using Innovative IIoT Technology

Maintenance & service are two of the most common application areas for IIoT solutions and the least profitable due to the existing business models. On the one hand, service processes can be optimized by networking machines and collecting and analyzing status/condition data, whether through the usage-dependent management of maintenance intervals or an improved first-time fix rate. This lowers costs and allows optimized deployment of highly qualified service staff.

On the other hand, new business models can be developed on the basis of continuous condition monitoring and enhanced data analytics in the form of extended service contracts, guaranteed availability or pay-per-use models. This can generate additional revenues and strengthen customer loyalty. valantic’s expertise and experience lets companies efficiently implement their IoT strategies in an objectives-oriented manner.

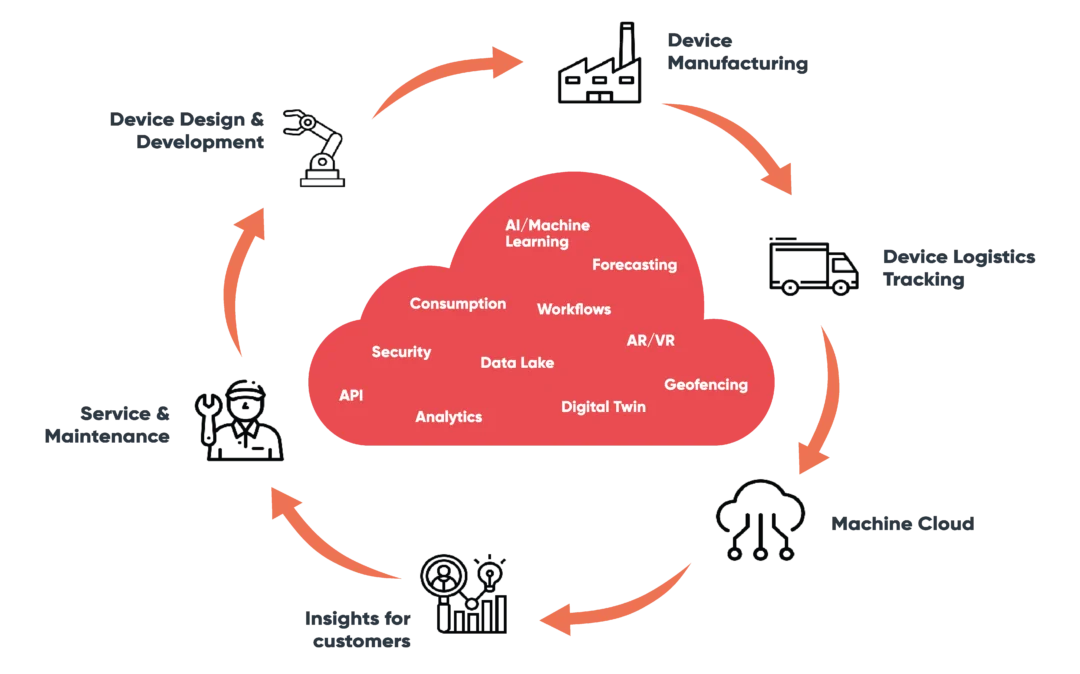

Device Management Using IoT and Digital Twins

Just like manufacturers of capital goods, the manufacturing industry, too, is currently facing enormous challenges. Sustaining innovation – i.e. the continuous technological rejuvenation of existing products – is now only one aspect of ensuring market success. Evolving customer expectations necessitate efficiency and quality improvements across the entire product lifecycle, as well as the creation of new business models. The basis for this is the technologies for creating a comprehensive data basis, therewith enabling the digital transformation of all processes: Industrial IoT and i4.0.

By networking machines, devices, sensors and IT systems, valantic creates IIoT platforms that allow products to be modeled as digital twins, thereby allowing the entire lifecycle to be monitored and steered. On this basis, a wide range of processes can be digitized, while simultaneously achieving significant quality and efficiency improvements.

The Complexity of Future IoT Applications

More Than Just a Device Cloud

IIoT platforms are more than just data lakes. Ideally, the digital twin contains information about the entire product lifecycle – from conception and commissioning through to maintenance. Only in this way can all the product-related processes be truly automated and end-to-end insights be generated.

Advanced Cloud Technologies & Services

Scalability, availability, cost, security – these are four of the key aspects that CIOs must today ensure for the applications and systems forming the digital backbone of companies. Increasingly, the response to these challenges is a move to the cloud. The main hyperscalers Amazon Web Services (AWS), Microsoft Azure and Google Cloud Platform offer infrastructure and managed services at a level that would only be possible in their customers’ own data centers at considerable cost. This is where “economies of scale” come into play.

As an AWS Advanced Consulting Partner and Microsoft Gold Partner, valantic offers a comprehensive service portfolio with which we accompany our customers on their journey to the cloud.

When we migrate our customers’ legacy systems and applications, we follow an established path that takes all aspects of this transformation into account.

During the development of new applications for our customers, our primary focus is on cloud-first and cloud-native. This means we design system architectures that optimally use hyperscaler services, while taking the above-mentioned requirements for performance, costs, scalability and security into account. The use of managed services allows applications to be developed and operated (DevOps) efficiently while meeting all the demands placed on mission-critical systems.

Low Code Turbo-Charges Digital Transformation

High-Quality Low-Code Apps Quicken the Path to Business Success

High-performance software that integrates customers, suppliers, partners and your own employees is rapidly becoming the cornerstone of digitalization and digital transformation. It streamlines processes, saves time, lowers costs and drives business growth.

Low-code technologies let developers build high-performance applications at speeds needed for businesses to stay competitive. valantic offers its customers expert support, helping them turbo-charge their digitalization initiatives and develop high-performance web and mobile applications using the OutSystems low-code platform.

Gartner has distinguished OutSystems with a top position in the Leaders Quadrant of its latest Magic Quadrant for Enterprise Low-Code Platforms.

valantic combines agile project management methodologies with high-quality low-code software development, guaranteeing outstanding results and faster time to market.

Accomplishing Digital Transformation with Low-Code

Based on the Low Code development platform OutSystems, valantic offers solutions for customers in diverse area.

Carbon Footprint, German Supply Chain Act and Taxonomy

Always One Step Ahead of the Competition Regarding Sustainability

Digitization principally also offers an opportunity to operate not only more successfully but also more sustainably, and to adapt a business to the challenges of climate change and the resulting social and legislative requirements.

To support our customers, we therefore offer the following services, among others:

- sustainable supply chain optimization in compliance with the German Supply Chain Act

- carbon footprint analyses

- sustainability consulting for companies and organizations

We want to shape digitization for the benefit of the environment and humanity, and to work toward ensuring our industrial customers can continue to turn raw materials into high-quality, commercially successful and safe products for as long as possible.

valantic is an expert in the future-proof digitization topics of industry and can thus present customers options for achieving their goals as easily and directly as possible.

We understand sustainability as a holistic approach, including social and economic issues additionally to environmental ones. This understanding influences our consulting style and our joint projects with customers.

More information on sustainability consulting for achieving your climate targets

Quick-Check Sustainability

Our quick-check on the topic of sustainability consulting provides you with important knowledge on what matters if you also want to make your company more sustainable.

Are You Ready for the German Supply Chain Act?

Since January 1, 2023, companies in Germany with more than 3,000 employees have been legally obliged to comply with their due diligence obligations within the supply chain.

Our Reference Customers

We have put together a short list of selected customer projects for you below in the form of Smart Industries & Industry 4.0 reference reports.

Blog News From Smart Industries

Learn more about our Smart Industries & Industry 4.0 topics in our blog.

Our Latest White paper

Benefit from our Smart Industries & Industry 4.0 experts’ know-how.

White paper: IT Consulting for the Automotive Industry

How to Profit From the Digital Structural Transformation.

E-Book: SAP End-to-End Demo case for discrete manufacturing industries (DMI)

Integrated SAP end-to-end planning and execution solutions using the example of Bike AG

Our Top Events

You can find useful information on Smart Industries & Supply Chain for your business in our webinars, webinars-on-demand and training/courses.

Job Vacancies Relating to Smart Industries

Your Contact

Martin Hofer

Partner & Managing Director

valantic Division Smart Industries