Highlight

Successful together – our valantic Team.

Meet the people who bring passion and accountability to driving success at valantic.

Get to know usFaster processes guarantee short delivery times

With our pre-configured SAP warehouse management solution, retail companies achieve optimized processes and short delivery times.

Solution for efficient SAP warehouse management

Growing challenges in (omnichannel) retail require effective warehouse logistics within supply chain management. With dynamic control of system-wide logistics processes, retail companies increase their ability to deliver and delivery rate. valantic cs4Warehouse, our pre-configured, scalable solution based on SAP Extended Warehouse Management (SAP EWM), offers innovative SAP warehouse management that meets all requirements reliably and efficiently.

The highlights at a glance

The technical basis of valantic cs4Warehouse is SAP S/4HANA-embedded SAP Extended Warehouse Management (SAP EWM) in the current release. Companies can therefore operate SAP EWM directly in SAP ERP; there is no need for the core interface. Alternatively, a decentralized EWM can be set up. Our solution template enables flexible mapping, management, and control of inventory and processes. valantic cs4Warehouse is designed in modular fashion and can be scaled as required, which means that even complex processes can be configured without gaps.

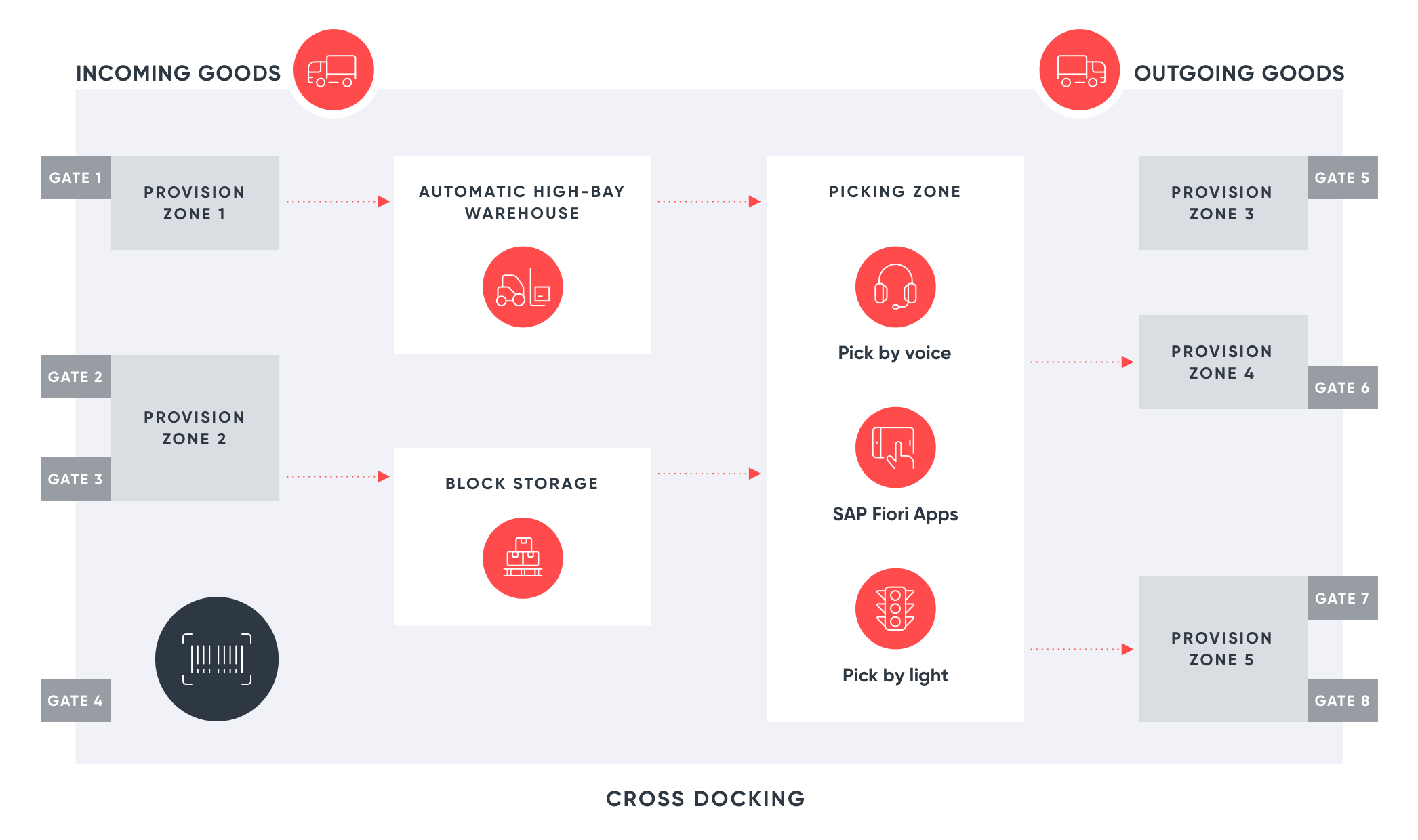

Among other things, valantic cs4Warehouse supports end-to-end cross-docking processes in SAP S/4HANA and SAP EWM, as required by retail for efficient goods management.

Integration with SAP S/4HANA enables direct use of retail functions. Operational activities can be carried out based on central transactions, which can also be displayed graphically. Therefore, inventory is transparent in all substeps. In addition, SAP EWM offers optimized functionalities in the areas of radio frequency identification (RFID), voice-assisted picking via pick-by-voice, direct communication with PLC systems, and ERP-initiated and plant-related batches. The graphical warehouse display can be adapted flexibly to local conditions and special goods requirements.

valantic cs4Warehouse offers numerous functions for dynamic SAP warehouse management. This includes transparent and prompt stock bookings, which ensure optimized storage capacities, the implementation of all incoming and outgoing goods, and reliable monitoring. Replenishment control can be set up automatically; stock availability for internal and external partners as well as for contract logistics makes operations cost-efficient.

With our solution, companies can coordinate storage locations and optimize routes. In addition, valantic cs4Warehouse offers innovative picking procedures for small orders, multi-order picking, automated picking waves, and RFID support to optimize time-critical processes. Extensive quality controls allow for a tailor-made provision to subsequent shipping and transport logistics.

Within the framework of an automated warehouse reorganization, incoming and outgoing goods zones, product line-specific storage areas, picking and reserve positions, not to mention return and quality areas can be planned and optimized. Companies benefit from application- and throughput-optimized incoming goods processes with efficient, even multi-stage processing of incoming goods. Unloading processes, quality checks, and deconsolidation can be controlled in a targeted manner. The automatic generation of pallets and labels and the handling of supplier returns are also possible. Process-oriented warehouse control enables multi-level storage and retrieval strategies. This helps with deconsolidation, quality control, and automatic packaging.