The example of Bike AG

End-to-End Processes in Discrete Manufacturing

The triad of planning, production, and delivery plays a central role in discrete manufacturing. The processes in these three phases should be ideally coordinated and end-to-end. To illustrate the best way in which SAP solutions can be used for this, an example will help.

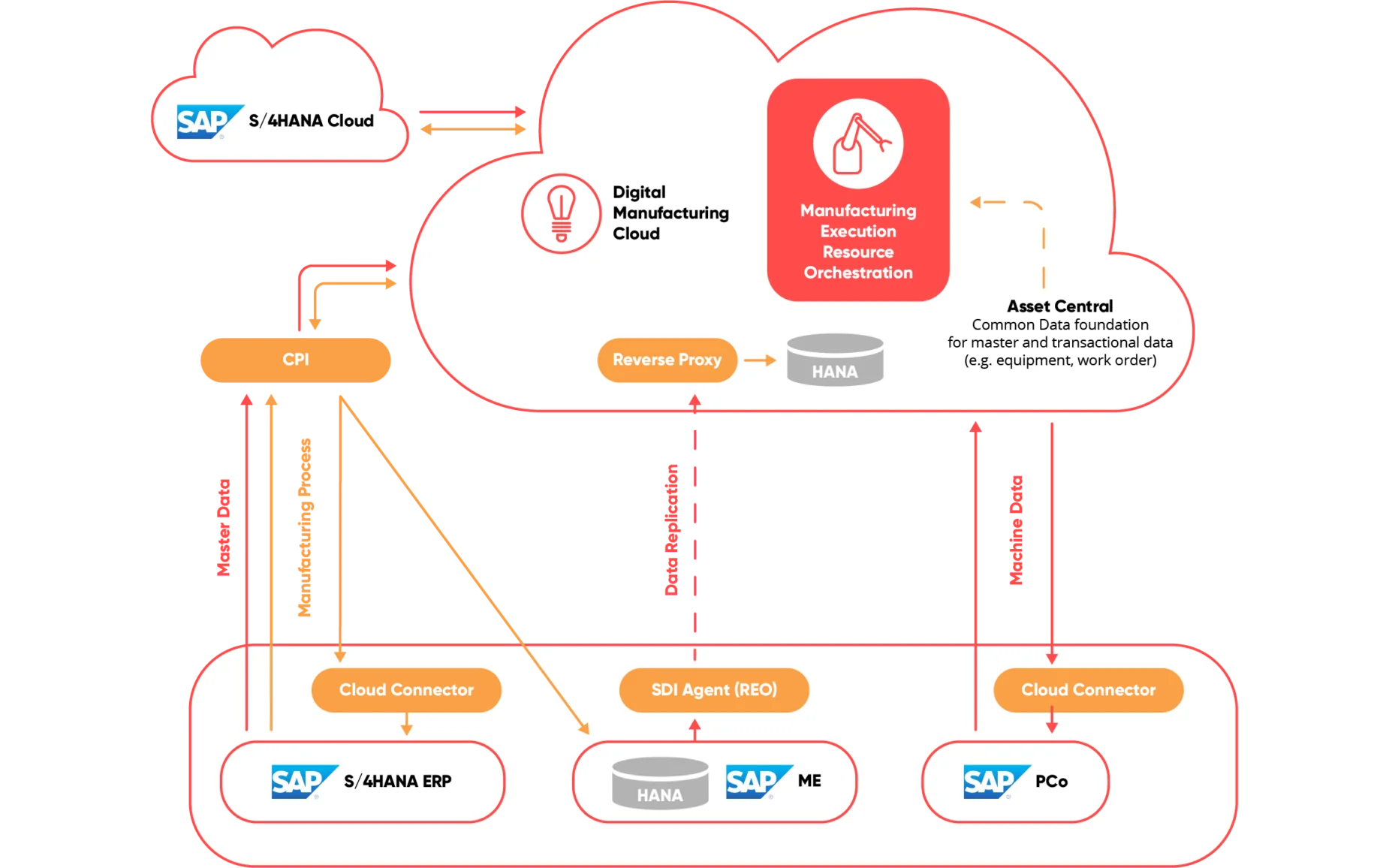

In the system demo developed by valantic, Bike AG, a fictitious manufacturer of bicycles, uses numerous SAP solutions: SAP Analytics Cloud (SAC), SAP Integrated Business Planning (IBP), SAP embedded Production Planning & Detailed Scheduling (ePP/DS), SAP Digital Manufacturing Cloud (DMC), and SAP Transportation Management (TM).

Plan. Manufacture. Deliver.

Bike AG is focusing on the following three main processes: Planning, manufacturing, and delivery. These three process sections mesh like gears and are interdependent. The best planning is of little use if there are issues in subsequent production. Optimal end-to-end planning is therefore extremely important companies in manufacturing industry.

Using a system demo as an example, valantic shows the added value of optimized end-to-end planning with integrated and networked processes for manufacturing companies. Using the example of a fictitious company engaged in discrete manufacturing, valantic shows how current and future customer needs are combined with the company’s own corporate goals and how requirements for transparency and the ability to plan in production are met.

E2E Processes in Discrete Manufacturing Industries

E-Book: Integrated SAP end-to-end planning and execution solutions using the example of Bike AG

IT landscape of end-to-end integrated SAP solutions

General data for Bike AG

-

1

Bike AG is a leading manufacturer of premium bicycles in the mid-range price segment.

-

2

Its portfolio consists of racing bikes, city bikes, and mountain bikes.

-

3

The components are procured on the global market, while assembly is done in Germany.

-

4

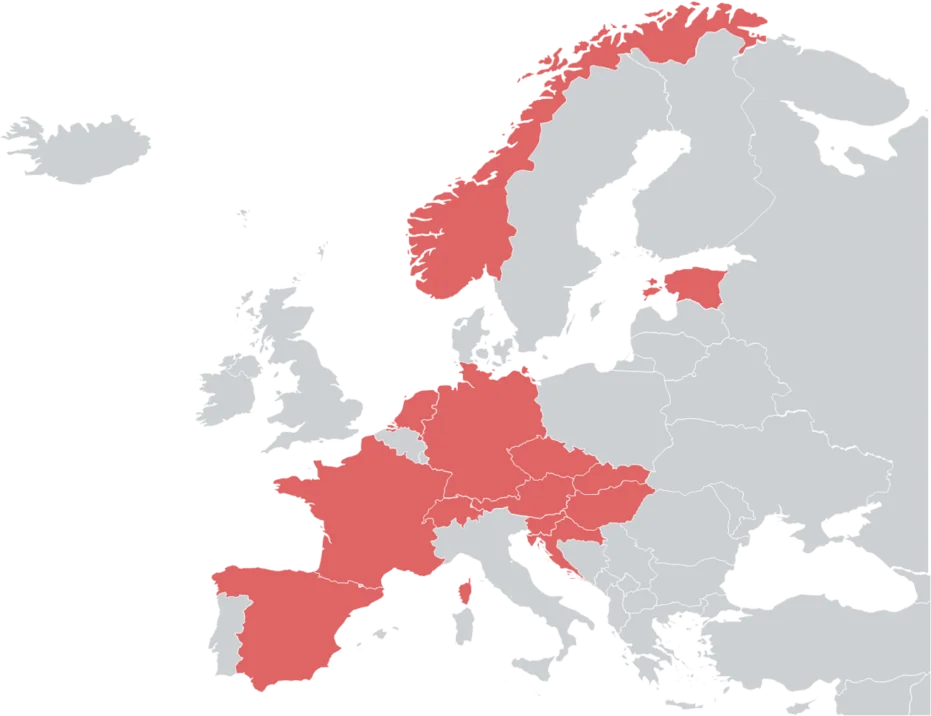

The most important sales markets are Germany, Austria, and Switzerland.

-

5

Delivery is done from a central warehouse, either to the dealer or to the end customer (online shop).

SAP End-to-End Processes in Discrete Manufacturing

Finance and sales & operations planning

Everything starts with strategic financial planning. Bike AG relies on SAP Analytics Cloud for this. It enables coordinated and integrated planning processes that are centrally managed and assigned to the responsible people. Simulations provide the basis for planned company development over the next few years. They are based on key figures, can be done visually, and planning master data can be created on the fly.

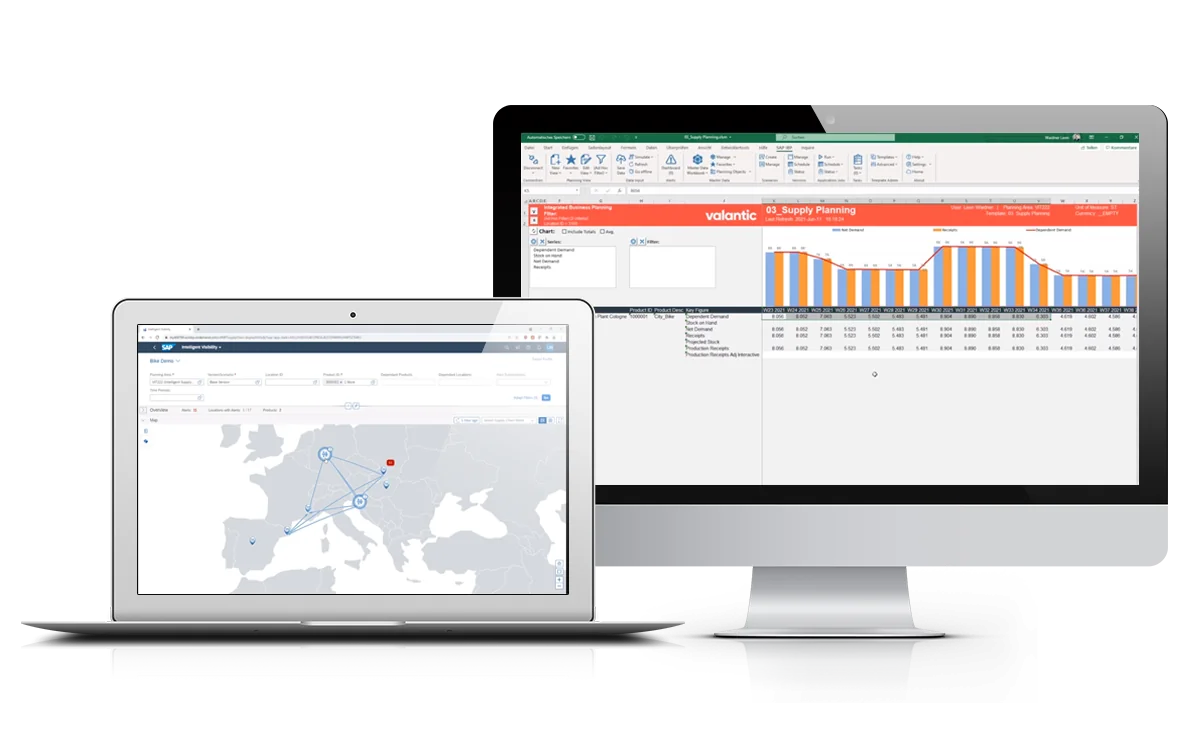

This financial planning will be integrated into the Sales & Operations Planning with SAP IBP and Ariba in the next step. This is a real-time aggregation of key figures from financial planning into demand planning. For example, Bike AG has statistical forecasts and target-actual comparisons available. After demand planning, the requirements are resolved and transferred to a capacity test. For this purpose, capacity information for the plants is retrieved from SAP S/4HANA and supplier capacities are exchanged via SAP Ariba. The direct connection to SAP Ariba enables a check of the planned component requirements. The goal is to hand over feasible planning to SAP S/4HANA.

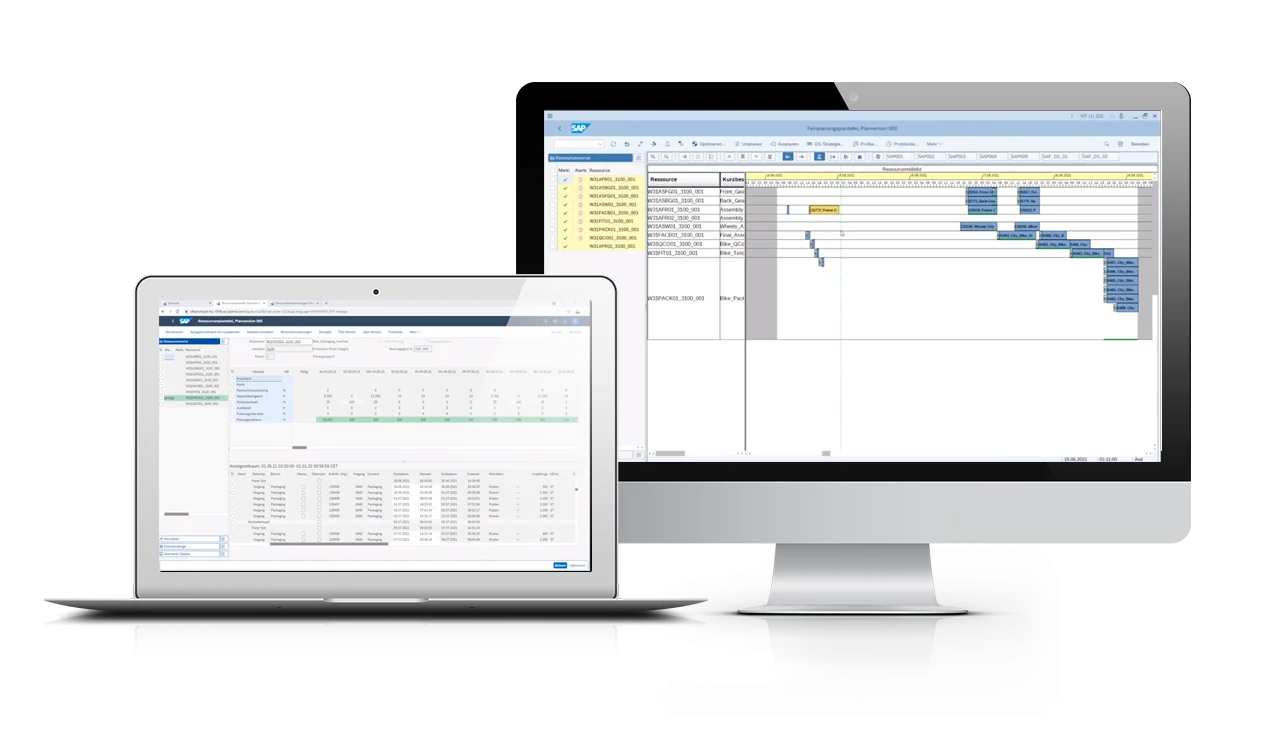

Production and detailed planning

Now the area of production fine planning follows. Embedded PP/DS enables production planning taking into account a feasibility check. On the one hand, it is important to check the availability of materials, e.g. bike seats. On the other hand, the ePP/DS checks in the context of a capacity check whether the capacities of plants are sufficient, and then optimizes the batch sizes and sequences of the individual production orders. Only in this way can the planned quantities be produced as cheaply and punctually as possible. A transparent presentation and a visualization of the production situation in apps and interactive planning tools are helpful. This is how the final production plan is created.

In the next step of the production process, released production orders can be transferred to the shop floor using the SAP Digital Manufacturing Cloud (DMC). The Digital Manufacturing Cloud offers automatic posting of incoming goods and an overview of the provision of bicycle components. It includes the warehouse logistics sector. Here, the bicycles produced and components for assembly removal are booked out of the warehouse.

Transport and delivery

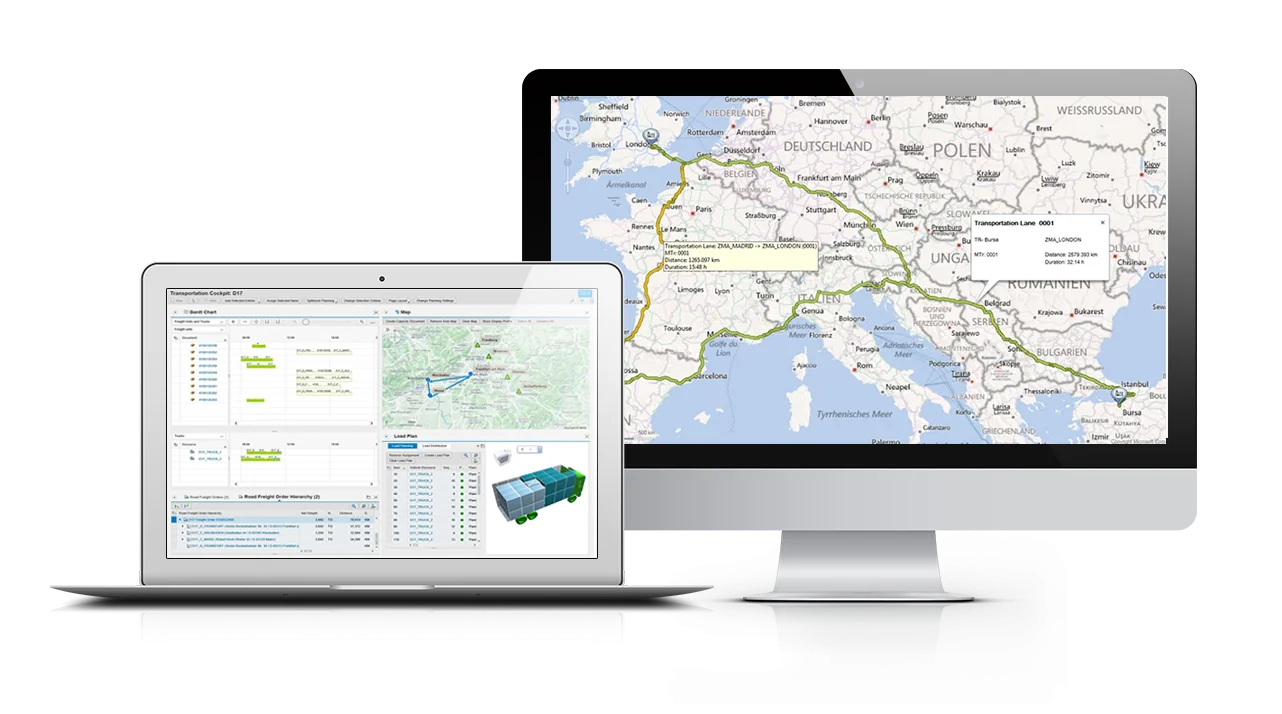

At the end of the value chain are transport and delivery. Bike AG’s bicycles can be taken from the production plant to the dealers or directly to customers via online shopping. With SAP TM (Transportation Management), all goods movements, whether order, purchase order, or transfer, can be planned and consolidated. The “Transportation Cockpit” offers extensive possibilities for planning transports in detail, assigning them to transport service providers, and tracking them. The SAP Logistics Business Network (LBN) offers the opportunity to work easily with transport service providers without having to implement complex interfaces. SAP LBN supports all common, transport-relevant processes, from procurement and document management to planning of gate assignment and resolving differences in invoicing.

The load planning is done completely automatically and visualized in 3D, the planned routes are displayed on a map and can be tracked in real time. SAP TM freight cost management offers the opportunity to fully map contracts with transport service providers, including all freight rates, so that the transport costs are automatically determined precisely and are available for SAP invoice verification. This way, Bike AG’s bikes reach their destination reliably.