Highlight

Successful together – our valantic Team.

Meet the people who bring passion and accountability to driving success at valantic.

Get to know usIn the midst of the pandemic, there was a major need for low-cost solutions to distribute medicines and vaccines to remote regions around the world. The German start-up Wingcopter became a major player in this field. With the wide range of uses for delivery drones in different countries, they need to comply with local regulations.

Wingcopter is a German manufacturer of electrically powered delivery drones that can take off and land vertically (so-called eVTOLs, vertical take-off and landing aircraft). This young company offers drone delivery services that, for example, optimize medical supply chains and ensure the logistics of the last mile for the delivery of urgently needed packages, tools, spare parts, and food. The vision of the 120-person team is to improve and save lives worldwide with meaningful commercial and humanitarian applications. Wingcopter is a Technology Pioneer of the World Economic Forum (WEF).

Wingcopter’s delivery drones are equipped to handle almost all weather and terrain conditions. Thanks to its patented tilt-rotor mechanism and software algorithms, the Wingcopter 198 can perform vertical take-off and landing maneuvers like a multicopter while flying long distances as efficiently and quickly as a drone equipped with rigid-fixed wings, even in rain and strong wind.

The Wingcopter 198 transports up to six kilograms of payload over a distance of up to 110 kilometers and reaches speeds of up to 110 kilometers per hour. The start-up’s investors include REWE Group, Salvia, XAI Technologies, Xplorer Capital, Futury Capital, ITOCHU, DROHNENFONDS, SYNERJET, EXPA, Hessen Kapital III, and Corecam Capital Partners.

Challenge

No release processes for 3D models, 2D drawings, and documents, no uniform standard product structure, the Data duplication became excessive and a recently launched PLM platform was not fully configured to meet all of these requirements

Consulting Approach

The PLM specialists of valantic analyzed Wingcopter’s processes, infrastructure, and business requirements

Customer Benefit and Solution

Developement of an integrated solution with four key components

Delivery drones are used for different tasks in various countries and must therefore be compliant to the requirements of the local authorities. This leans to a significant variance in the planning and production of unmanned flight systems. That’s why Wingcopter was looking for a strategic PLM (Product Lifecycle Management) solution to manage the various components and product configurations efficiently and transparently for everyone involved in the value creation process.

In addition, different challenges were hampering the innovation process and efficiency of manufacturing processes at Wingcopter:

valantic’s (former sandborn digital’s) PLM specialists analyzed Wingcopter’s processes, infrastructure, and business requirements and developed an integrated solution with four key components:

Plattform governance

Product data management

Lean fast-track change, release, and approval process

End-2-end change process

Tool configuration for (approving) user groups, route templates

PLM Wiki community and knowledge base

Three months of excitement

In early 2021, when large parts of the world were in Corona lockdown, the German start-up Wingcopter sought help for implementing its newly acquired PLM platform 3DExperience. During the Corona pandemic, efficient and cost-effective solutions for distributing medicines and vaccines were in great demand around the world, even in remote regions. With its delivery drones, Wingcopter offers just the right solutions for this. The German start-up had already achieved its first successes before Corona, with its electrically powered delivery drones, which can also take off and land vertically. Medical deliveries were made in Vanuatu, Malawi, and Scotland as part of drone test flights. Test data from these flights confirmed the drones’ performance and functional characteristics and attracted great interest from customers and investors.

Delivery drones are used for many, very different tasks and therefore have to comply with the different requirements of the local authority. This presents significant challenges for Wingcopter’s engineers responsible for planning, configuration, and production. They are confronting a kind of squaring of the circle: The aim is to adapt each product individually to the customer’s requirements and at the same time further develop the uniform product baseline.

These conflicting requirements have the potential to put any start-up into a precarious situation. The right PLM strategy, which starts as early as possible in the product life cycle, is therefore particularly important. Transparency, efficiency, and the entire company’s success depend on this strategy, especially in the aerospace industry, which cannot afford the start-up luxury of a “fail fast, fail often” culture. Wingcopter had to do everything right the first time.

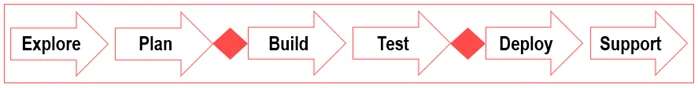

Project phases of the joint PLM project that put Wingcopter back on track and significantly increased its agility and efficiency

All stakeholders were aware of the importance of the PLM project at Wingcopter from the outset. At the beginning of the exploratory phase, valantic’s experts conducted a top-down capability assessment, which consisted of interviews and workshops with the most important stakeholders. All relevant topics from corporate strategy to detailed functional requirements were captured. The conversations enabled valantic’s consultants to provide all relevant information about the customer, its work culture, schedules, processes, budgets, problems, and impacts. A subsequent fit-gap analysis outlined possible solution architectures.

In the subsequent planning phase, the team subjected each solution and its interfaces to a rigorous assessment and then prioritized them – with full transparency for the customer – in a multi-phase schedule based on work packages. As a result, Wingcopter and valantic now had a common understanding of the task ahead. All results were summarized in a mutually agreed set of requirements and a PLM roadmap.

Wingcopter was not the kind of PLM newbie you might expect a young start-up to be. The engineering team had excellent 3D modeling capabilities (CATIA) and had already developed lean, innovative production processes such as 3D printing for rapid prototyping. During the exploratory phase, however, it turned out that the product data was too cumbersome and required too much maintenance to manage all product configurations transparently and clearly. Without a stringent concept, the repeated “copying and pasting” of design data generated data proliferation that was a real risk. Wingcopter’s engineers ran the risk of losing track of the status of their basic and variant designs.

Sustainable concepts for product data management must therefore be able to track all installed components throughout all product maturity phases and manage product variants efficiently. This requires simplified data structures and processes that drive innovation rather than stifling it. It is also critical to get end users on board as early as possible and explain the value of the new data and process discipline.

A basic principle of valantic’s consulting approach is therefore to put the focus on people. The consultants find the best solution in consensus with the customer. One of the solutions on the roadmap, for example, was to implement a PLM Wiki community and knowledge base that stakeholders can access using the 3DSwym app in 3Dexperience. This way, end users are involved in developing the delivery drones from start to finish.

In the development phase, valantic and Wingcopter formed a team of key users who were also owners of their solution cluster. Together with the key users, the ready-to-use, final solution was then developed and refined further using agile scrum methodology. Practical trainings followed (train the trainer). The subsequent cascading test phase examined the fulfillment of all requirements through functional application scenarios in the tool. Key users, chief engineers and selected end users kept a watchful eye on the test results and provided feedback. After successful completion of all acceptance tests, the valantic project manager published the user guidelines on the PLM Wiki and began the coordinated implementation of the PLM solution.

After just over three months, the implemented solution had put Wingcopter back on track. And perhaps more importantly: The engineering team at Wingcopter had become a collaborative entity, due simply to the way the overall project was conducted.

Are you dealing with similar challenges? Please feel free to contact us for a non-binding meeting to get to know each other. We look forward to hearing from you.

Dieter Dragon

Managing Director

valantic