Highlight

Successful together – our valantic Team.

Meet the people who bring passion and accountability to driving success at valantic.

Get to know usKNAPP AG

In order to reduce order throughput times, optimally utilize capacities, and increase on-time delivery, the company continuously improves its planning organization and processes. The APS system wayRTS plays a central role in this.

Optimization of planning organization and planning processes

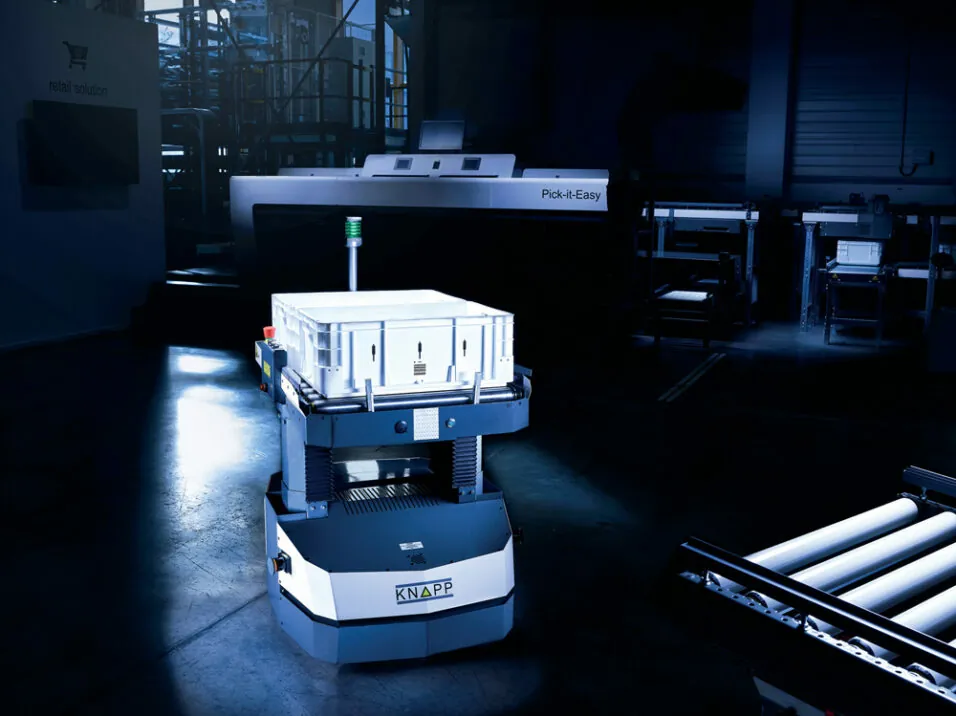

KNAPP group provides all-in-one solutions for automation and digitalization, from production and distribution to the point of sale. The technology partner, headquartered in Austria, develops and manufactures intelligent warehouse systems using the latest solutions in digitalization, software, automation and robotics. Because customers in industries such as healthcare, fashion, retail, food retail, and industry require individual solutions to manage their complex intralogistics processes, KNAPP’s business is project-driven. In order to reduce order throughput times, optimally utilize capacities, and increase on-time delivery, the company continuously improves its planning organization and processes. The APS system wayRTS plays a central role in this.

Results & customer benefit

Cross-divisional process understanding, joint control of production

Rapid deployment of basic principles for management decisions thanks to scenario simulation

Transparency of supply chains with controlled defective part management

Central scheduling through order management

End-to-end control with KPIs

Detailed deadlines and worklists

KNAPP is the technology partner for intelligent value chain management. Headquartered in Austria, the KNAPP group provides all-in-one solutions for automation and digitalization, from production and distribution to the point of sale. Excellent service and long-term collaboration make KNAPP the strong partner behind the success of their customers in the sectors healthcare, retail, food retail, fashion, wholesale and industry.

The company develops and manufactures intelligent warehouse systems using the latest solutions in digitalization, software, automation and robotics. At KNAPP, innovation, internationality and team spirit are highly valued. Worldwide, the company has about 7,000 employees, each bringing their individual backgrounds, qualifications and points of view to the table, but what unites them all is the passion they feel for their work. Providing first-class service within long-term collaborations makes KNAPP the strong partner behind the success of their customers. Their customers include the food retailer SPAR, the pharmaceutical wholesaler Herba Chemosan, the fashion brand Hugo Boss, and the e-commerce giant Zalando as well as many others.

The initial situation

Since the beginning of the collaboration, when wayRTS was implemented in parallel with an SAP ERP system migration, the people at KNAPP responsible for production planning and valantic’s SCM consultants have been conducting workshops where they search constantly for optimization opportunities. One challenge became clear early on: There were a whole series of planning systems that had to be synchronized manually. Scheduling responsibilities were distributed among several people and departments and were often not transparent. A critical interface in the process was the transition from engineering to production planning. Inventories were sometimes too high, long runners were only discovered very late in the process. Management of defective parts was time-consuming, started too late, and was spread across different systems. One of the causes: The previously maintained set-up costs and batch size optimization stood in contrast to a consistently order-based production.

Centralized planning enables smooth utilization

From the very beginning, realignment of supply chain management for the planning processes was approached holistically. The SAP consultants worked hand-in-hand with valantic’s experts, whose APS system wayRTS has deadline authority and is responsible for the transparent planning of order fulfillment without any backlog. A big advantage of wayRTS: Real-time simulations also enable planners to identify the indirect, “hidden” effects of their decisions and to approach the optimal utilization of production capacities. The generally binding planning is then generated in wayRTS.

Integrated Project Management with wayPRO

SAP with a material resource planning and a connected engineering data management system is the leading data system at KNAPP AG. Developing customized solutions to manage material flows is a very project-based business.

First, an interface to the ASTA PowerProject project management system was created. However, in its long-term cooperation with valantic, the company also benefits from the enhancement of the waySuite S&OP software suite, which now offers integrated project management with wayPRO. This improves long-term planning, including forecasting opportunities for procurement. The Excel shift plans can also be replaced with wayWFM Work Force Management. The planning for approximately 700 employees is better integrated into capacity planning.

The success of these measures is due to the fact that KNAPP succeeded in establishing a new, cross-divisional process understanding with a view to an overall optimal state: Away from local optimizations such as set-up optimization, toward an overall view across all production stages. Order management is responsible for central scheduling, which must be accepted by all specialist departments. Today, production meetings are held at KNAPP on a daily basis to coordinate and control the production process accordingly.

KPIs align with the overall optimal state

An important prerequisite for such centralized order planning is meaningful master data. This means that the BOMs must be process oriented. Due to the BOM resolution in MRP (Material Resource Planning), KNAPP also automated variant creation and scheduling. Internal Order Management works paper-free – documents are printed directly in production where they are still needed. Detailed deadlines and worklists allow more precise control of production.

The great advantage of the new planning organization and using wayRTS is that transparency prevails throughout the entire production chain. Planning is based on meaningful KPIs that align with the overall optimal state.

Example: The buffer indicator shows how many days before the planned delivery date the material will be transferred to dispatch. wayRTS provides the data this requires. This metric is important for scheduling dates and storage locations.

If components are available too early, it must be clarified whether an earlier delivery to the construction site is possible or whether additional storage space for buffering the materials is required. Although wayRTS only plans until the handover to dispatch, the people responsible for installation at the customer’s site benefit from the transparency of upstream processes.

Project demand is the trigger, but does not restrict planning

As an important optimization approach, it was clear to KNAPP from the transparent planning that its parts production is now 100% anonymous. The trigger is always a specific project requirement, but in production the parts are combined into optimal batches that combine requirements for several projects. In assembly, 5% are treated anonymously in this way, the remaining 95% are assigned.

Crisis-proof thanks to transparent planning

Prior to March 2020, KNAPP’s planners had to process up to a maximum of ten schedule-critical network planning elements per working day. At the peak of supply chain problems, this figure rose to 1200; by the end of 2022, it was about 200. Nevertheless, all this has only minimal (if any) impact on customers, as internal measures compensate for the subsequent process steps. The formulation of the compensatory measures is based on wayRTS.

This is how KNAPP deals with missing purchased parts and delivery bottlenecks: wayRTS automatically indicates a delivery bottleneck and is also the data source for all further agreements. The subsequent delivery of the components to be installed is marked as open components in the SAP user status, and the dispatch delivery date is initially postponed. To prevent SAP from automatically allocating the oldest demands first, a blocked special stock has been set up so that it can be prioritized manually. In coordination with purchasing, production, project management, and assembly, an additional allocation of small quantities is carried out via prioritization.

Important advantages that KNAPP enjoys since it started using APS system wayRTS:

Mass processing and anonymous production

Better overview of production processes

User-configurable views

Easier to learn than SAP PPS

Efficient defective part assessment and tracking of the required measures throughout the entire process chain

Precise shift scheduling

Better scalability

Multi-user / multi-plant capability

Adaptable to process changes in production